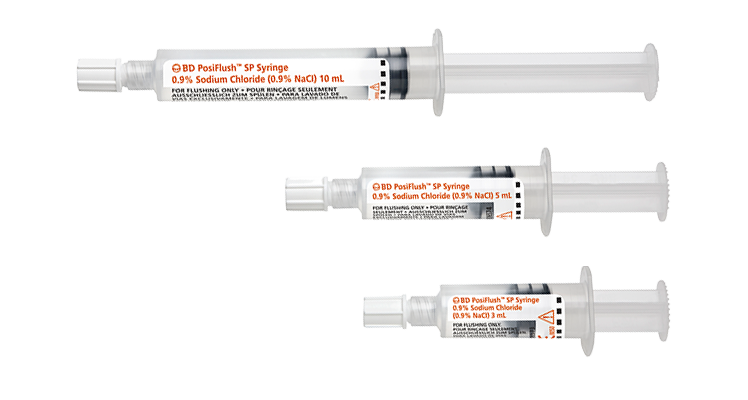

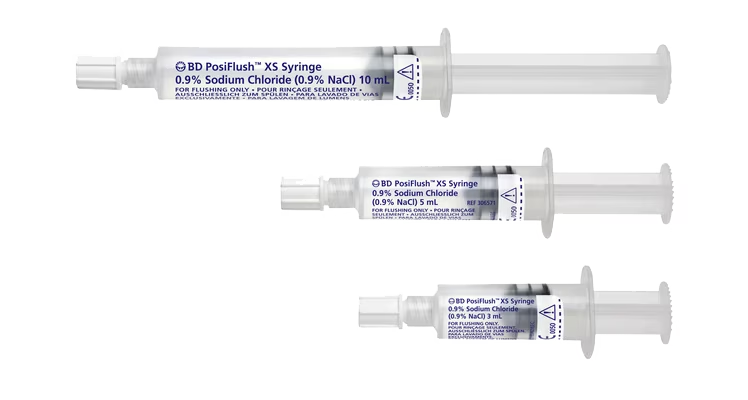

BD PosiFlush™ SP Prefilled Saline Syringes are designed to improve clinician efficiency and workflow by reducing the time involved in the manual preparation of saline syringes.1 They are intended to be used for the flushing of indwelling vascular access devices.

Catheter type and size, medication as well as some of the patient characteristics should determine the flush volume being used in order to properly maintain catheter patency and reduce medication interactions.2